Facilities

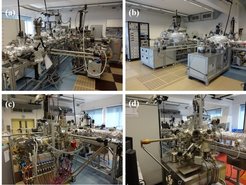

The thin film laboratory is equipped with a state-of-the-art ultra-high-vacuum (UHV) cluster tool for the growth and characterization of thin films [Fig. 1(a)]. The cluster has two magnetron sputtering systems one with thirteen and the other with eight sources [Fig. 1(b)]. Both are equipped with direct current (DC) and radio frequency (RF) sources for the growth of various metallic, semiconducting, and insulating films. The target-to-substrate distance can be varied and the substrate holder can be rotated during the deposition to ascertain homogenous film growth. The maximum reachable substrate temperature is 1000 °C. All the processes are computer-controlled to guarantee reproducible high-quality films.

Additionally, the cluster has a Molecular Beam Epitaxy (MBE) system for the growth of high-quality epitaxial thin films [Fig. 1(c)]. The MBE is equipped with six effusion cells for depositing a variety of different materials. In situ growth control is achieved by Reflection High Energy Electron Diffraction (RHEED). Low Energy Electron Diffraction (LEED) and Auger Electron Spectroscopy (AES) are attached to the system for surface structure and chemical analysis, respectively.

Furthermore, an angle-resolved photoemission spectroscopy (ARPES) system [Fig. 1(c)] and a scanning probe microscope (SPM) [Fig. 1(d)] are attached to the cluster for the in situ characterization of the fabricated films [Fig. 1(c)]. The ARPES allows to determine the electronic structure of surfaces, and the UHV-SPM system combines the functionalities of a scanning tunneling microscope (STM) and an atomic force microscope (AFM). All the above equipment is inter-connected by a UHV transfer-line so that samples can be transferred in UHV conditions.

Our laboratory is equipped with different characterization techniques to evaluate the quality of thin films and heterostructures. It includes a high-resolution four-cycle X-ray diffractometer to characterize the crystal structure, thickness and the interfaces, AFM for surface analysis, magnetic force microscopy (MFM) with variable in-plane and out-of-plane magnetic field for the observation of magnetic domains. Further, a Physical Property Measurements System (PPMS) widens the possible methods for measurements of the electrical resistance, Hall effect. In additional, the Seebeck coefficient and Nernst effect can be measured in patterned nanoscale devices.

The cluster also allows us to characterize bulk samples and to utilize them as substrates. The layout of the laboratory is adopted from a typical cleanroom and offers a separated double door system for changing shoes and a technical room that houses roughing pumps, gas cabinets, and cryo pumps. The main laboratory is equipped with a raised floor (colored as periodic table), which also acts as the inlet for the air conditioning system. All needed media such as cooling water, power, and gas lines are installed below this floor.

Here, are summarized the thin film growth and characterization techniques

Growth

Sputtering deposition systems

Molecular beam epitaxy system

Characterization

X-ray scattering

AFM/MFM

PPMS

ARPES

SPM (STM and AFM)

XPS

Auger