Al2Pt for oxygen evolution reaction in water splitting: a strategy for creating multi-functionality in electrocatalysis

The transition from fossil fuels to renewable energy sources strongly depends on an availability of effective systems for energy conversion and storage. Considering hydrogen as a carrier molecule, proton exchange membrane electrolysis offers numerous advantages, like operation at high current densities, low gas crossover, compact system design etc. However, its wide implementation is hindered by slow kinetics of oxygen evolution reaction (OER), enhancement of which requires the application of low-abundant and expensive Ir-based electrocatalysts. Looking for rational design of new types of OER electrocatalysts and addressing fundamental questions about the key reactions in energy conversion, the inter-institutional MPG-consortium MAXNET Energy integrated the scientists from different institutions in Germany and abroad. As a result of close and fruitful collaboration within this framework, the scientists from Chemical Metal Science department at MPI CPfS together with experts from Fritz Haber Institute in Berlin and MPI CEC in Mülheim an der Ruhr, developed a new concept for producing multifunctionality in electrocatalysis and successfully illustrated it with an example of intermetallic compound Al2Pt as precursor for OER electrocatalyst material.

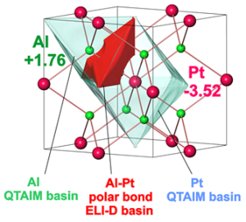

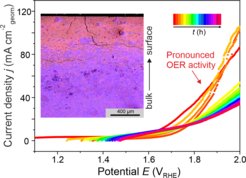

Intermetallic compound Al2Pt (anti-CaF2 type of crystal structure) combines two characteristics important for electrocatalytic performance: (i) reduced density of states at the Fermi level of Pt, and (ii) pronounced charge transfer from aluminium towards platinum, leading to strongly polar chemical bonding in this compound (Figure 1). These features provide inherent OER activity (Figure 2) and increasing stability against complete oxidation under harsh oxidative conditions of OER. Upon OER conditions, Al2Pt undergoes restructuring in the near-surface region as a result of the self-controlled dissolution of aluminium (inset of Figure 2). The roughness and porosity of in situ-formed near-surface microstructure allow to compensate the specific activity loss. Even after exceptionally long stability experiment (19 days) at high current densities (90 mA cm-2) the bulk material retains its structural and compositional integrity. Extending the choice of synthesis techniques, e.g. thin films growth, and exploring the variety of intermetallic compounds draw the main guidelines for future development of the proposed strategy.

Iryna Antonyshyn/IA

Figure 1. Atomic QTAIM basins of platinum and aluminium (transparent) and Al-Pt bond basin (red) in the Al2Pt compound, revealing the pronounced charge transfer from Al to Pt atoms and polar character of Al-Pt atomic interactions.

Figure 2. Long-term OER experiment in 0.1 M HClO4 with Al2Pt anode, expressed viaseries of linear sweep voltammetry curves, recorded after every 24 h of chronopotentiometry at 90 mA cm-2. Inset: EDX spectrum image of the top 1.2 mm of the sample after the long-term experiment (cross section view; Al-rich domains in blue, Pt-enriched grains in red).