Magnetocalorics - L. Caron

Magnetic refrigeration based on the magnetocaloric effect (MCE) represents the most promising alternative to gas compression refrigeration, yielding up to 50% improved efficiency. The effect can generate substantial temperature changes around room-temperature, particularly in materials undergoing magnetostructural transitions i.e. simultaneous magnetic and structural transitions. These transitions are induced by external magnetic fields and can be composition-tuned over wide temperature ranges, making them ideal for cooling applications.

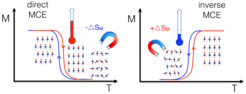

Heusler alloys are extremely interesting materials for applications based on the magnetocaloric effect due to the possibility to combine magnetic and structural (martensitic) phase transitions to obtain both direct and inverse MCE. Since the transition temperature and magnetocaloric properties in Heusler alloys are highly compositional dependent, the effect can be easily tuned by varying the composition.

Figure 1: Schematic diagram of conventional and inverse MCE’s with thermal hysteresis in Heusler alloys. At high temperature material has cubic austenite structure, which changes to low symmetry martensite structure at low temperatures.

In our group we have long-time experience designing magnetic Heusler alloys. We fine-tune the compositions to get low twinning stress and volume conserving martensite transition. The modulation and lower c/a ratio in martensite phase are important for low twinning stress and thus for the reversibility of phase transformation and MCE.

Figure 3: Time dependences of the adiabatic temperature change at in Ni50Mn35In15 Heusler alloy at 6 T (top) and 20 T (bottom), measured in pulsed magnetic fields.

We investigate the structural and magnetic properties of magnetocaloric Heusler materials. Aiming at applications, we do the direct adiabatic temperature change measurement using pulsed magnetic fields. For example, we have measured the direct adiabatic temperature change in Ni50Mn35In15 under pulsed magnetic fields up to 20 T. Such measurements provide the response of the sample in frequencies (10–100 Hz) comparable to those of magnetocaloric cooling devices.

Challenges and goals:

- large reversible adiabatic temperature and entropy changes in low applied magnetic fields (0.5~1.5 T)

- small thermal and magnetic hysteresis

- broad working temperature range 250-350 K

- low raw materials and production costs

- non-toxic